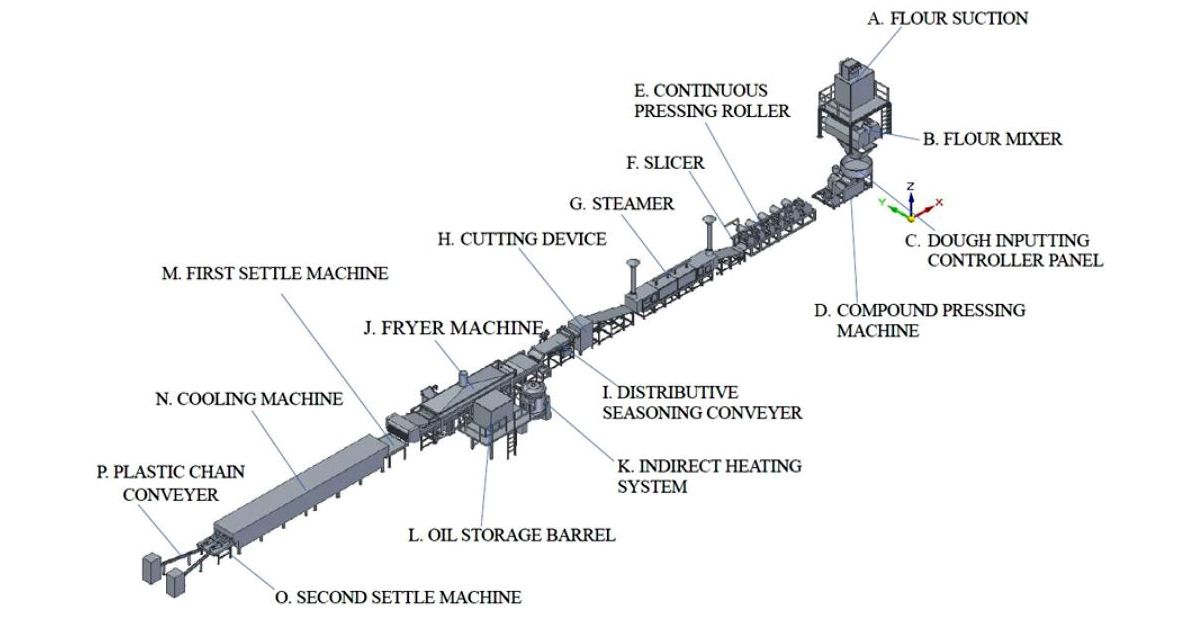

Instant Noodle Production Line (Bag / Bowl Type)

Instant noodles are the most popular noodle products in the market. No matter it is taste, convenience, long shelf life & reasonable price, it has been recognized by people all over the world. The instant noodle manufacturing process is mixing, compounding, continuous pressing, steaming, cutting and folding, seasoning, frying, and then cooling. The steaming time is about 120 seconds. The steam heat source is produced through the boiler. The noodles are steamed, and the waving noodles can be shaped. Before entering the frying, the customers can choose whether to make the noodles preliminary seasoning or tasting. In order to make the aroma and flavor of noodles better, you can use falling device or spraying device to add the seasoning or sauce on the noodles.

The frying temperature is controlled around 160 ~ 170°C. The frying time is about 100 ~ 120 seconds. During deep frying, the water content of noodles will be dehydrated instantly at high temperature environment. The cooling time is about 180 seconds, and the noodles which after frying will be cooled down the temperature while doing cooling. So that the noodles can enter the packaging equipment directly. In addition, after the noodles are fried at high temperature, the water content of noodles is about 3% to 5%. After the noodle is packed with film in roll and 3 side sealed pillow pack, it can be stored for about 6 months. After frying the noodles, the noodles will create numerous porosities. So that when cooking, hot water can quickly penetrate these porosities and soften the noodles. Then, you can eat the noodles only in few minutes. This is the convenience way of instant noodles.

If you share your ideas with us, we can make a proposal on all the equipment needed.

Please feel free to contact us!

A. FLOUR SUCTION

B. FLOUR MIXER

C. DOUGH INPUTTING CONTROLLER PANEL

D. COMPOUND PRESSING MACHINE

E. CONTINUOUS PRESSING ROLLER

F. SLICER

G. STEAMER

H. CUTTING DEVICE

I. DISTRIBUTIVE SEASONING CONVEYER

J. FRYER MACHINE

K. INDIRECT HEATING SYSTEM

L. OIL STORAGE BARREL

M. FIRST SETTLE MACHINE

N. COOLING MACHINE

O. SECOND SETTLE MACHINE

P. PLASTIC CHAIN CONVEYER

Making Processing

Mixer → Compound → Continuous Pressing → Steaming → Frying → Cooling

- Using Flour Mixer to mix salt, water, flour and other formulas evenly.

- Dough dropped into the Compound Pressing Machine to produce dough sheet and make it more flat and solid.

- Passing the dough sheet to Continuous Pressing Roller to press from thick to thin.

- The final roller with slicer to cut the dough sheet to become noodle strips and make waving.

- Waving noodles are steamed to finalize the noodle shape.

- Then, cutting and folding the noodle to become noodle cake and delivering to Fryer Machine.

- After frying, delivering the noodle cakes to Cooling Machine and can be packed.

- Roller: Each roller has independent motor, and using inverter to control speed.

- Steamer: Using exhaust hoods to reduce steam leakage.

- Fryer Machine: Oil removing windmill to reduce oil content of noodle cakes.

- Cooling Machine: Using hot fan to cool down the temperature of noodle cakes which after frying.

- Safety Device: Each roller is equipped with the sensor to sensing dough passing; The whole machine is equipped with emergency stop button.

- All product contact surface area is stainless steel or food grade material.

Machines

| (1) Lye Mixer Tank | (2) Lye-Measuring Tank | ||

|---|---|---|---|

| [Product Information] Volume: 1,000 / 1,200 L To mix required liquid (salt, water and formula) together evenly All product contact surface area is stainless steel or food grade material. |  | [Product Information] Volume: 50 / 100 / 150 L Only using for batch type flour mixer. Automatic liquid level controlling by plc. Measuring required liquid and pump to mixer directly. All product contact surface area is stainless steel or food grade material. |

| (3) Flour Suction | (4) Flour Mixer | ||

|  | ||

| (5) Dough Inputting Controller | (6) Compound Pressing Machine | ||

|  | [Product Information] First process to make dough sheet: Pressing dough to dough sheet, then combining two dough sheets to one dough sheet. Independent motor, using inverter & sensor to control speed. Includes the thickness indicator. All product contact surface area is SUS304 construction. Emergency stop switch device & sensor. | |

| (7) Continuous Pressing Roller | (8) Slicer | ||

| [Product Information] Pressing the dough sheet from thick to thin. Independent motor, using inverter & sensor to control speed. Includes the thickness indicator. 3/4/5/6/7 section rollers for option. Wave type rollers for option. All product contact surface area is SUS304 construction. Emergency stop switch device & sensor. |  | |

| (9) Steamer | (10) Cutting Device | ||

| [Product Information] One level; three level; five level. Steaming the noodles and finalizing the noodle shape. Steam times: according to different products. Using exhaust hoods to reduce steam leakage. All product contact surface area is stainless steel or food grade material. |  | |

| (11) Distributive Seasoning Conveyer | (12) Fryer Machine | ||

|  | [Product Information] Deep fry the noodle cakes. Including oil removing windmill to reduce oil content of noodle cakes. Using exhaust hoods to reduce the leakage of oil fumes and heat. All product contact surface area is stainless steel or food grade material. | |

| (13) Indirect Heating System | (14) Oil Storage Barrel | ||

| [Product Information] Made in Japan. Steam type; spiral heat exchanger. High efficiency and small size. Not easily retain stains and easy to clean. |  | |

| (15) First Settle Machine | (16) Air Cooling Machine | ||

|  | [Product Information] Cooling time: 3 mins (standard) Using the fans to cool down the temperature of noodle cakes which after frying. All product contact surface area is SUS304 construction. | |

| (17) Second Settle Machine | (18) Plastic Chain Conveyer | ||

|  | ||