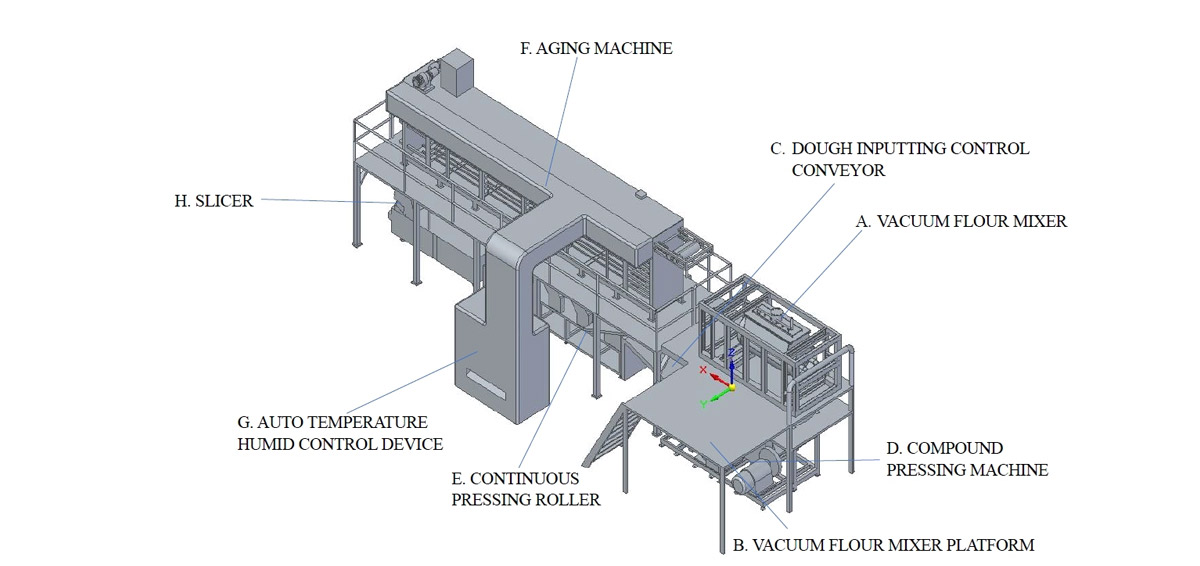

Automatic Fresh Noodle Production Line

- Making Processing:

Mixer→Compound→Continuous Pressing→Cutting- Using Vacuum Flour Mixer to mix salt, water, flour and other formulas evenly.

- Dough dropped into the Compound Pressing Machine to produce dough sheet and make it more flat and solid.

- Passing the dough sheet to Continuous Pressing Roller to press from thick to thin.

- The final roller with slicer to cut the dough sheet to become noodle strips.

- Special Function:

- Vacuum Flour Mixer:Operated by HMI interface. The final products will be more chewing after evacuating the air

- Roller:Each roller has independent motor, and using inverter to control speed.

- Slicer:Various sizes available, different slicer to cut different noodle, for example, udon, ramen and butterfly noodle…etc.

- Safety Device:The mixer tank is equipped with anti-pinch device.;Each roller is equipped with the sensor to sensing dough passing; The whole machine is equipped with emergency stop button.

- All product contact surface area is stainless steel or food grade material.

- Option:

- Dough Sheet Fold Device:The dough sheet folded with straight line continuously, improve the gluten structure though pressing the dough sheet.

- Aging Room:Under constant temperature and humidity (24~27℃ / 80~90% RH), aging dough sheet about 20-30 minutes in order to extend the noodle elasticity.

- Automatic Roll Noodles Machine:Rolling noodles automatically and easy to take out.