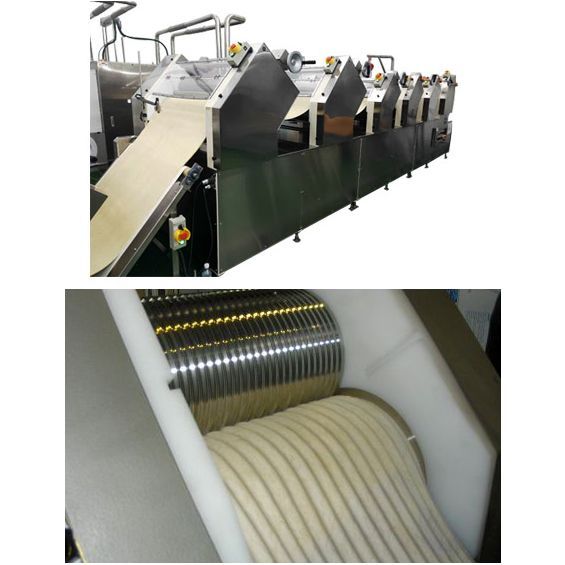

Automatic Steam-Cooked Noodle Production Line

The steam-cooked noodle manufacturing process is mixing, compounding, continuous pressing, steaming, cutting and water cook / water wash. We design Vacuum Flour Mixer to mix flour and other formula. Firstly, the internal air of the mixer tank is evacuated, and mixing dry powder about one minute. Then, adding alkaline water to the mixer and mixing about 15 - 20 minutes with high/low speed. After completely mixing, the tank will turn down 180° to discharge the dough to Dough Inputting Controller automatically. Because the air in the mixer has been evacuated, the dough after mixing will be more solid.

Dough dropped into the Compound Pressing Machine to produce dough sheet to make dough sheet more flat and solid. The operation way of Continuous Pressing Roller is to press and stretch the dough sheet which from Compound Pressing Machine. Step by step, the dough sheet from thick to thin. After being pressed and stretched continuously, the gluten in the dough becomes stronger. The final section of Continuous Pressing Roller is with slicer and waving device. Using slicer to cut the dough sheet to become noodles with wave. Then, enter to steam box to make noodles gelatinize. During steaming process, steam and heat can enter the noodle completely because of the gap of waving noodles. Also, finalizing the noodle shape. Then, cutting the specified noodle length by the customer quantitatively. Noodles will drop into the noodle box for cooking directly. The water inside of cook machine is about 100°C. According to different products, the cooking times is different, too. After cooking, noodle will drop into the noodle box for washing. Through normal water temperature 26 - 28°C to wash off excess gluten and cool down the noodle temperature to pack directly.

If you share your ideas with us, we can make a proposal on all the equipment needed.

Please feel free to contact us!

Machines

| (1) Lye Mixer Tank | (2) Lye-Measuring Tank | ||

|---|---|---|---|

| [Product Information] Volume: 1,000 / 1,200 L To mix required liquid (salt, water and formula) together evenly All product contact surface area is stainless steel or food grade material. |  | [Product Information] Volume: 50 / 100 / 150 L Only using for batch type flour mixer. Automatic liquid level controlling by plc. Measuring required liquid and pump to mixer directly. All product contact surface area is stainless steel or food grade material. |

| (3) Flour Mixer | (4) Dough Inputting Controller | ||

|  | [Product Information] To choose either one, conveyor or panel. Using linkage arrangement to discharge the dough flour. All product contact surface area is SUS304 construction. Includes the crusher. Using crusher stick to break dough and deliver to compund pressing machine. | |

| (5) Compound Pressing Machine | (6) Continuous Pressing Roller | ||

| [Product Information] First process to make dough sheet: Pressing dough to dough sheet, then combining two dough sheets to one dough sheet. Independent motor, using inverter & sensor to control speed. Includes the thickness indicator. All product contact surface area is SUS304 construction. Emergency stop switch device & sensor. |  | [Product Information] Pressing the dough sheet from thick to thin. Independent motor, using inverter & sensor to control speed. Includes the thickness indicator. 3/4/5/6/7 section rollers for option. Wave type rollers for option. All product contact surface area is SUS304 construction. Emergency stop switch device & sensor. |

| (7) Slicer | (8) Steamer | ||

|  | [Product Information] One level; three level; five level. Steaming the noodles and finalizing the noodle shape. Steam times: according to different products. Using exhaust hoods to reduce steam leakage. All product contact surface area is stainless steel or food grade material. | |

| (9) Strentching + Cutting Device | (10) Water Cook / Wash Machine | ||

|  | [Product Information] Two types noodles using: Udon / Ramen Cooked times: max. 12 minutes Indirect heating / automatic temperature control. Hot water inside the tank and temperature cycle system. Twice cutting / one cutting for one pitch. Three level cooling tank (can add twice time cooling system). Noodle wash device. Sterilization piping. Cool and hot separate design. Capacity: 2,000 / 4,000 / 6,000 packs / Per Hr: (200g / pack) | |

| (11) 4-Doors Type Sterilization Oven | |||

| [Product Information] Pasteurizaton Oven: Trough high temperature and steam to do pasteurizaton and adjust PH value to extend the shelf life. | ||